Electrotherm (India) Ltd., established in 1983, is a diversified engineering conglomerate serving the steel, foundry, and equipment sectors. With a strong focus on innovation and technology, Electrotherm designs and manufactures induction melting furnaces, metal refining converters, high-speed casting machines, and induction heating systems.

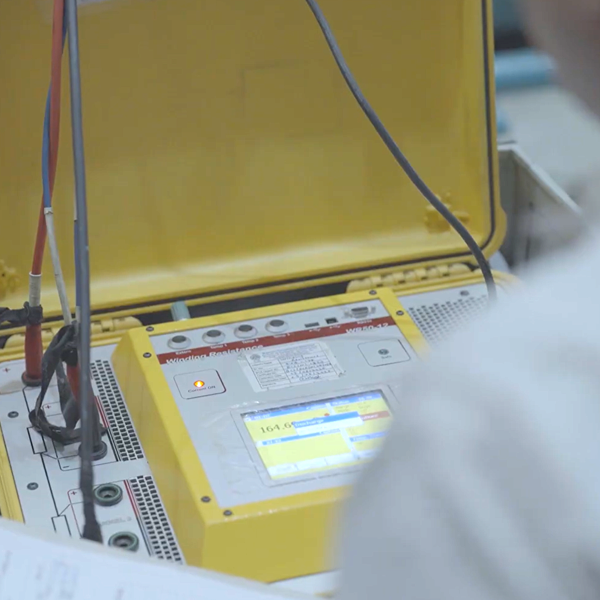

To meet the demanding conditions of steel melt shops and improve operational efficiency, Electrotherm implemented Pro-face’s PS6000 IPC, ET6000 and SP5000 HMI series, along with GP Viewer and Remote HMI software. These solutions have enabled their engineering team to simplify process visualization and enhance system reliability.

Background and Challenges

Steel manufacturing environments are extremely dusty and harsh. Equipment must withstand oil, heat, and vibration while remaining easy to operate and maintain. Electrotherm needed a solution that could offer:

- Robust hardware for harsh industrial conditions

- Easy-to-use graphical interfaces for process mapping

- Seamless integration with third-party systems

- Secure and scalable remote monitoring capabilities

Solutions - Why choose Pro-face Products-

Simply

Using PS6000 IPC with GP Viewer and Remote HMI, Electrotherm engineers can easily visualize and control processes. The wide screen range (8" to 22") and intuitive graphics make it simple for operators to monitor operations in real time.

Reliability

Pro-face IPCs are designed to meet IEC 62443 standards and are ATEX and Marine certified, ensuring secure and reliable performance in demanding steel industry environments.

Engineering Efficiency

The Pro-face IPC Configurator allows Electrotherm to customize IPCs based on end-user requirements and send configurations directly to the factory—saving time and reducing errors.

Connectivity

With over 200 communication drivers, Pro-face HMI and IPCs integrate seamlessly with third-party PLCs and SCADA systems, enabling centralized control and monitoring across multiple applications.