KAWANOE ZOKI CO., LTD. has been manufacturing paper machines and paper processing machinery since its founding and boasts an 80% share of the domestic market for household tissue-making machines. Kawanoe Zoki Co., Ltd. is continuously striving to do better and take on the challenge of being a trusted company and chosen by their customers. In this interview, we asked KAWANOE ZOKI CO., LTD. about the reason why they have continued to use Pro-face HMI since its introduction in 1992.

Customer Story Key Figures

15% Total Cost Saving

-----------------------------------------------------------------------------------------------------------------

About the first HMI Solution with Pro-face

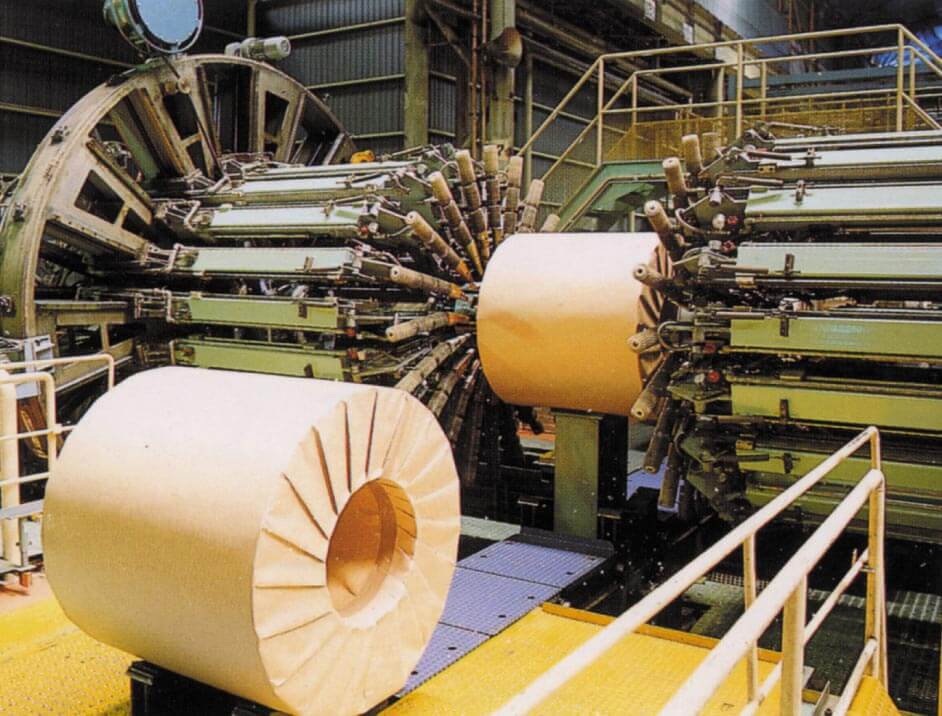

The first time we used an HMI was for a coil wrapping machine. This is a machine for winding steel plates used for automobile bodies. Initially, we used digital switches and digital displays to manage data such as the type of material to be packaged and information about the amount of material remaining, but this was very cumbersome when changing them, so we decided to use an HMI to manage the data, and in 1992 we introduced the GP430 for the first time.

Development History with Pro-face HMIs

When we got used to HMI Software, we introduced it to the wrapping machine. The data that had been managed on the PC was gradually moved to the HMI System. Then came the era of the GP70 series, and the drawing software settings were changed from tags to designs for placing parts, which made drawing very easy. After the release of the GP577R (especially after the GP2000 series), we began to use it more and more as an operation panel for equipment. There was a dominant belief that it had to be a push-button system, but the equipment's operability has changed dramatically with the HMI introduction. This is easy to understand because people could see the information immediately, like when switching between recipes. This means that the system can be operated intuitively. Another advantage of the Pro-face HMI is that it is easy to expand the functions using the software. We have recently started to use tablets to operate the machine, mainly to improve efficiency during commissioning.

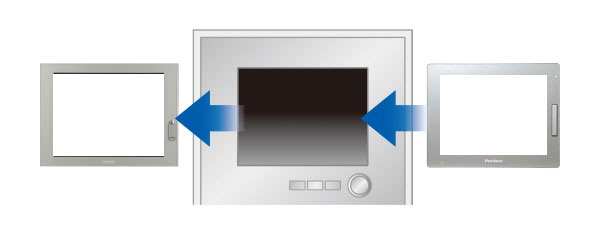

Effortless Migration and HMI updating

First, Pro-face HMIs made it convenient to use past drawing data. With the Project Converter, we were able to change models relatively smoothly. When we changed the model from monochrome to color, it took some effort, but we feel that the software was excellent in making the most of our assets. The GP477R, which was discontinued in 2009, and the GP2000 series, which was discontinued in 2011, are still in operation. If our customers request a change of model or there is a failure (mainly due to a broken backlight), we can update to the GP4000 Series or a later model. The equipment we develop is designed to be used for a long period (10 to 20 years), but in some cases, the customer has a need to update the HMI, so the ease of migrating the HMI is essential. In general, migration tools such as project converters, accessories, conversion cables, etc., are fully equipped and updated without any problems. Another point that makes it easy to migrate is the fact that both analog and matrix touch panel types can be selected and the operability of the equipment can be inherited and migrated. This is undoubtedly one of the reasons why we have continued to use Pro-face HMI since its introduction in 1992.

-----------------------------------------------------------------------------------------------------------------

To ensure ease of use and upgrading, we will continue to develop compatible HMIs and accessories, user-friendly software, and services/support with the HMI Centric concept. We are now providing a migration guide on the Pro-face website to smoothly migrate older HMI models to the latest technology. You can find all the necessary information in this book. It will help you in “ Effortless migration to innovations.”

Kakemizu Koji

Design Department, KAWANOE ZOKI CO., LTD.

KAWANOE ZOKI CO., LTD.

Since 1994, Kawanoe Zoki has been developing, designing, manufacturing paper machines (Household tissue making machine, Paper converting machine). The company works on nonwoven manufacturing equipment in recent years and provides consistent total engineering from designing, manufacturing, installation, and start-up. Our sales territory is expanding to China, Taiwan, Vietnam, and Southeast Asia.

Recommend Article & Video

[Video] How to empower workforce with HMI Centric concept?

[Video] How can we bring humans at the core of the digital revolution while maintaining system robustness?

[Article] Increasing information value in 3 Steps by effectively processing information with Pro-face.